Transforming Wastewater Treatment

Leveraging plunging micro bubbles to lower costs, conserve energy, eliminate N2O emissions, and contribute to climate action objectives.

Wastewater innovation experience over 20 years

Mixanox offers unique solution options for treating wastewater and sludge (biosolids), using

best-of-breed biological treatment methods with fast installation times, low costs, and energy-efficient ways, therefore unlocking the full potential of existing infrastructures.

APPLICATIONS

Mixanox developed a versatile mixing and mass transfer technology for improving process performance and energy efficiency to help conventional wastewater treatment plants, whether retrofitting anaerobic, anoxic and aerobic reactors or enabling MBBR / IFAS in existing reactors.

Use our universal mixing tool,

PIJAMA®, as a plugin for your system. It includes standard equipment/parts, e.g., pumps, manifolds, and nozzles. Which

PIJAMA® fit your application?

TECHNOLOGY

PIJAMA®

PIJAMA® stands for for

Plunging

Immersed

Jet

Aspiration

Mixing

Apparatus. It is a mixing and mass transfer technology with fast installation time, low costs, easy operation and simple maintenance, which helps wastewater treatment plants

gain real benefits from their existing infrastructure, also helping to meet "Net Zero" GHG emission targets faster.

Patented in the EU, USA, Canada

Universal mixing and mass transfer

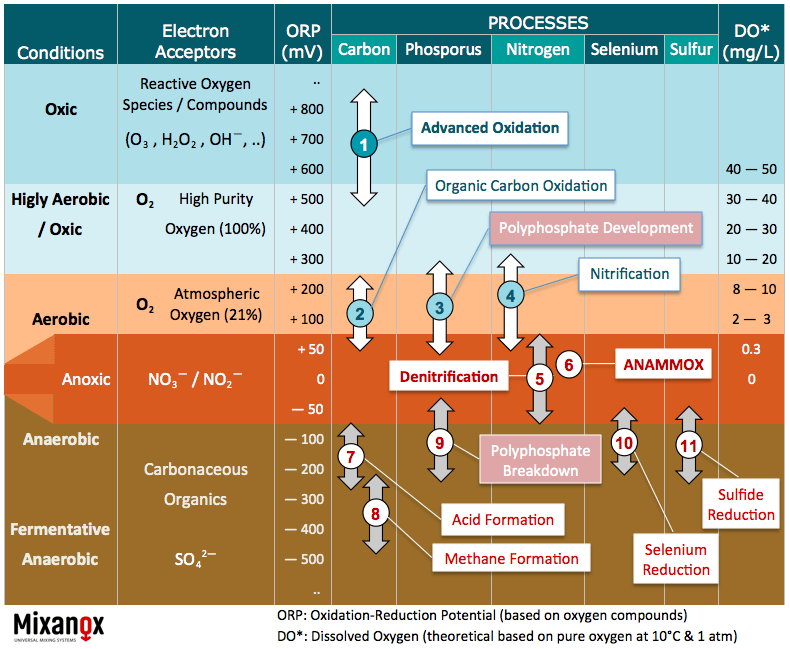

PIJAMA® can be plugged into any existing reactor, whether it is under anaerobic, anoxic, aerobic, or oxic conditions. As a result, it facilitates a universal mixing system that is simple to install and easy to maintain.

Targeted wastewater reactions are shown below table.

EXAMPLE APPLICATIONS

Video-1: Multiple Uses

Video-2: Upgrade Existing

Unlocking Value with Our Technology

Discover the Advantages:

Cost-Efficiency

- Save up to 50% or more on both capital expenditures (CAPEX) and operational expenses (OPEX)

Effortless Installation and Service

- Seamless wet installation without disrupting existing processes

- Easily serviceable non-proprietary parts like pumps, pipes, and manifolds

- Maintenance-free reactor with no moving parts in the liquid

- Key components are semi-submerged and easily removable

- Simplified maintenance procedures for enhanced operational efficiency.

- Quick periodical servicing in minutes, not hours

- Major servicing completed within hours, not days

- Swift access to critical parts ensures minimal downtime.

- Streamlined maintenance with minimal labor hours

Adaptability

- Plug-and-play system for existing reactors, ensuring rapid setup and commissioning

- Tailor equipment choices to match local preferences, no blackbox parts and

no dictated equipment brands

Enhanced Process Performance

- Drastically reduce off-gas and emissions including N2O emissions by up to 95% to contribute climate action objectives

- Cold climate optimization leads to higher reactor temperatures and superior biological nitrification/denitrification efficiency.

Video-4: MBBR / IFAS

Video-6: Plug-in Example

Video-7: Algal-Bacterial

COLLABORATION

Call for Commercialization Partner

Our patented technology—agnostic design approach allows customers with "Wastewater and Sludge Treatment" plants to bring in the best application solution independently of their existing infrastructure to enable fast implementation technology applications with rapid ROIs and installation times to achieve "Net Zero" GHG emission targets faster.

R&D Collaboration / Commercialization Partnership Contact: partnership@mixanox.com

Seeking Collaboration for R&D Growth

- Anoxic applications (#1) (e.g. ANAMMOX®, MBBR/IFAS, and SHARON )

- Anoxic application (#2) for autotrophic low pH novel nitrifiers: AOBs like Nitrosospira and NOBs like Nitrospirae

- Oxic applications (e.g. intermittent Ozone assisted aerobic sludge digestion for EDC, PAH removal)

- Combined applications

[ e.g. RAS (Recirculating Aquaculture Systems) requiring aerobic (O2), anoxic, and oxic (O3) gas transfer along with carbon-dioxide (CO2) degassing ]